Introduction

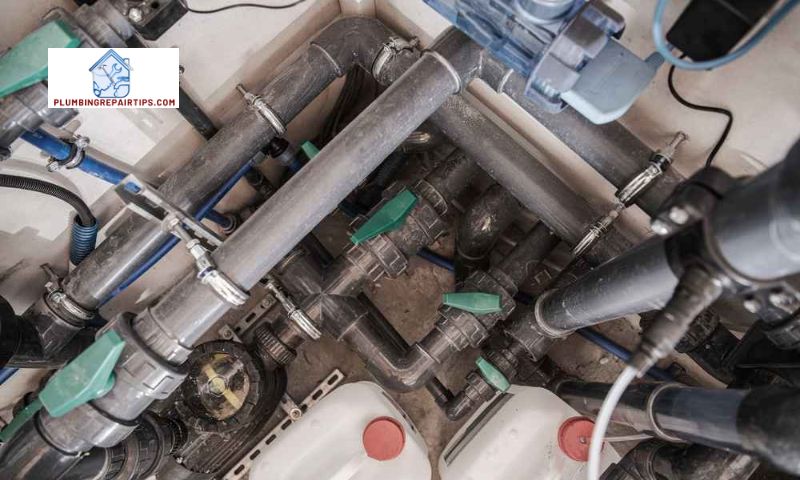

In the world of industrial processes, activated carbon systems play a crucial role in various industries. Have you ever heard about Pipe leak repair for activated carbon systems? Discover at plumbingrepairtips.com! These systems are relied upon for their exceptional ability to purify air and water, remove contaminants, and ensure optimal performance. However, like any complex system, activated carbon systems are not immune to issues. One common challenge that arises is the occurrence of pipe leaks within these systems.

When pipe leaks occur in activated carbon systems, the consequences can be far-reaching and detrimental. Leaks not only disrupt the system’s functionality but also pose significant risks to both the environment and the overall operation. That’s why it is essential to address pipe leaks promptly and efficiently.

Understanding Pipe Leaks in Activated Carbon Systems

Pipe leaks in activated carbon systems can occur due to various reasons, such as corrosion, aging, or improper installation. These leaks can compromise the efficiency of the system, leading to reduced purification capabilities and potential contamination issues. Moreover, if left unattended, pipe leaks can escalate into more significant problems, causing costly downtime, environmental damage, and even safety hazards.

To mitigate these risks, it is crucial to recognize the signs and symptoms of pipe leaks in activated carbon systems. By identifying these indicators early on, you can take proactive measures to prevent further damage and ensure the system operates optimally.

Stay tuned for the upcoming sections where we will explore the signs and symptoms of pipe leaks in activated carbon systems, provide step-by-step guidance for repairing these leaks, and offer preventive measures to avoid future occurrences. Together, we will equip you with the knowledge to safeguard your activated carbon system and maintain its efficiency.

Understanding Pipe Leaks in Activated Carbon Systems

Definition and Causes of Pipe Leaks in Activated Carbon Systems

Pipe leaks in activated carbon systems refer to the unintentional escape or seepage of fluids through cracks, holes, or faulty joints within the system’s piping network. These leaks can be caused by a variety of factors, including:

- Corrosion: Over time, the corrosive nature of certain fluids or the presence of chemicals can deteriorate the pipe material, leading to leaks.

- Aging Infrastructure: As activated carbon systems age, the pipes may become weakened or develop cracks, making them more susceptible to leaks.

- Improper Installation: Faulty installation practices, such as inadequate sealing or improper connections, can create weak points in the piping system, increasing the likelihood of leaks.

Potential Consequences and Risks Associated with Pipe Leaks

The consequences of pipe leaks in activated carbon systems can be significant, impacting both the system’s performance and the surrounding environment. Some of the potential risks include:

- Reduced Efficiency: Pipe leaks can disrupt the intended flow of fluids within the system, diminishing its overall efficiency in purifying air or water.

- Contamination: Leaking pipes can introduce contaminants into the purified fluid, compromising the quality and safety of the output.

- Financial Loss: Unaddressed pipe leaks can lead to increased utility costs due to wasted fluids, as well as potential damage to equipment and infrastructure.

- Environmental Impact: Pipe leaks can result in the release of harmful substances into the environment, polluting water sources or contributing to air pollution.

Importance of Early Detection and Preventive Measures

Early detection of pipe leaks is crucial to minimize the risks and consequences associated with activated carbon systems. Implementing regular inspections and monitoring techniques can help identify leaks at their earliest stages, allowing for prompt repairs and preventing further damage.

In addition to proactive detection, preventive measures play a vital role in avoiding pipe leaks altogether. Proper installation practices, routine maintenance, and the use of high-quality materials can significantly reduce the likelihood of leaks, ensuring the long-term efficiency and reliability of activated carbon systems.

Stay tuned for the upcoming sections where we will delve into the signs and symptoms of pipe leaks, provide step-by-step guidance for repair, and offer preventive measures to safeguard your activated carbon system. Together, we will equip you with the knowledge and tools to tackle this common issue effectively.

Signs and Symptoms of Pipe Leaks in Activated Carbon Systems

Pipe leaks in activated carbon systems can have detrimental effects if not detected and addressed promptly. Therefore, it is essential to familiarize yourself with the signs and symptoms that indicate a potential pipe leak. By being vigilant and proactive, you can mitigate the risks and prevent further damage to your system.

3.1 Description of Common Indicators that Suggest a Pipe Leak

Identifying the signs of a pipe leak in an activated carbon system is crucial. Some common indicators include:

3.1.1 Decreased System Performance

If you notice a sudden decline in the efficiency of your activated carbon system, it could be a sign of a pipe leak. Reduced purification capabilities, decreased flow rate, or compromised filtration efficiency may indicate a leak compromising the system’s overall performance.

3.1.2 Unusual Water or Air Flow

Pay attention to any abnormal water or airflow within the system. Gurgling sounds, fluctuating pressure, or inconsistent flow patterns could be indicative of a pipe leak.

3.1.3 Water or Air Discoloration

Observe any changes in the color or appearance of the water or air being processed by the activated carbon system. Discoloration, cloudiness, or the presence of sediment can be signs of a leak, as contaminants may be seeping into the system.

3.2 Identifying Leaks through Visual Inspection and Monitoring Systems

Performing regular visual inspections is crucial for detecting pipe leaks in activated carbon systems. Inspect the pipes, fittings, and connections for any signs of corrosion, cracks, or water stains. Additionally, monitoring systems such as pressure gauges, flow meters, or leak detection sensors can provide real-time data, alerting you to potential leaks.

3.3 Discussion on the Importance of Regular System Checks

Regular system checks are essential to catch pipe leaks early on and prevent further damage. By implementing a proactive maintenance schedule, you can identify and address potential issues before they escalate. Conduct routine inspections, monitor system performance, and promptly address any abnormalities to ensure the optimal functioning of your activated carbon system.

Stay tuned for the next section where we will delve into the steps for repairing pipe leaks in activated carbon systems. With the knowledge of detecting leaks and understanding their significance, you will be better equipped to maintain the efficiency and longevity of your system.

Steps for Pipe Leak Repair for Activated Carbon Systems

Preparation and Safety Measures

Before embarking on the pipe leak repair process, it is crucial to prioritize safety and adequately prepare for the task at hand. Here are some essential steps to follow:

- Ensure System Shutdown: Begin by shutting down the activated carbon system to prevent any further leakage or damage. This will allow you to work on the repair without risking additional complications.

- Safety Gear: Put on the appropriate safety gear, including gloves, goggles, and protective clothing, to protect yourself from any potential hazards during the repair process.

Necessary Tools and Materials

To effectively repair pipe leaks in activated carbon systems, you will need the following tools and materials:

- Pipe Repair Kits: Invest in high-quality pipe repair kits that are specifically designed for the type of pipe material and size used in your activated carbon system. These kits typically include repair clamps, epoxy putty, and sealing materials.

- Pipe Cutters: Depending on the severity of the leak, you may need to cut out the damaged section of the pipe. Ensure you have the appropriate pipe cutters or saws to make clean and precise cuts.

- Wrenches and Screwdrivers: Have a set of wrenches and screwdrivers on hand to loosen and tighten any connections or fasteners during the repair process.

- Cleaning Supplies: Before applying any repair materials, it is essential to clean the affected area thoroughly. Prepare cleaning supplies such as brushes, solvents, and rags to ensure a clean surface for the repair.

Step-by-Step Guide for Repairing Pipe Leaks

Repairing pipe leaks in activated carbon systems requires a systematic approach. Follow these steps for a successful repair:

- Locate the Leak: Identify the exact location of the pipe leak. This can be determined by visual inspection, listening for hissing sounds, or using leak detection equipment if necessary.

- Prepare the Pipe: Clean the area around the leak using the appropriate cleaning supplies. Ensure the surface is dry and free from debris before proceeding.

- Apply Repair Materials: Depending on the extent of the leak, use the pipe repair kit to apply the appropriate repair materials. This may involve wrapping the damaged area with repair clamps or using epoxy putty to seal the leak.

- Secure and Test: Follow the manufacturer’s instructions to secure the repair materials in place. Once the repair is complete, turn on the activated carbon system and carefully monitor the repaired area for any signs of leakage.

By following these steps, you can effectively repair pipe leaks in your activated carbon system, ensuring its continued operation and minimizing any disruption to your industrial processes. Remember, if you are unsure or the leak is substantial, it is always recommended to seek professional assistance to ensure a thorough and reliable repair.

Preventive Measures for Pipe Leak Prevention in Activated Carbon Systems

Pipe leaks in activated carbon systems can be costly and disruptive. To avoid such issues and ensure the smooth operation of your system, implementing preventive measures is crucial. By taking proactive steps and conducting regular maintenance, you can minimize the risk of pipe leaks and enhance the longevity of your activated carbon system.

Importance of Regular System Maintenance and Inspections

Regular maintenance and inspections are paramount in preventing pipe leaks in activated carbon systems. By adhering to a comprehensive maintenance schedule, you can identify potential issues and address them before they escalate into significant problems. Regular inspections allow you to detect signs of corrosion, wear and tear, or other vulnerabilities that may lead to pipe leaks.

Furthermore, maintenance activities such as cleaning, lubricating moving parts, and replacing worn-out components can significantly contribute to the prevention of pipe leaks. These routine tasks ensure that your system remains in optimal condition, reducing the chances of unexpected failures.

Various Preventive Measures to Avoid Future Pipe Leaks

- Proper Installation: Ensuring proper installation of the activated carbon system is the first step in preventing pipe leaks. Properly fitted pipes, secure connections, and appropriate sealing techniques are essential to minimize the risk of leaks.

- Regular System Checks: Perform routine checks to identify any signs of deterioration, corrosion, or damage to pipes or fittings. Inspect for loose connections, worn-out gaskets, or any other potential vulnerabilities.

- Proactive Replacement: Replace aging or deteriorating pipes, fittings, and seals before they reach their breaking point. It is advisable to follow the manufacturer’s recommended replacement schedule to maintain the system’s integrity.

Tips for Proactive Measures and Early Detection

- Monitor Pressure Levels: Keep an eye on the pressure levels within your activated carbon system. Sudden fluctuations or abnormal readings may indicate a potential pipe leak.

- Implement Leak Detection Systems: Consider installing leak detection systems that can alert you to the presence of leaks. These systems utilize sensors to detect moisture or changes in pressure, providing early warnings.

- Train Staff on Leak Awareness: Educate your staff on the importance of leak awareness and provide guidance on how to identify and report potential leaks promptly. Encourage a culture of vigilance and proactive communication.

By implementing these preventive measures and staying vigilant, you can significantly reduce the likelihood of pipe leaks in your activated carbon system. Remember, prevention is always better than dealing with the aftermath of a leak.

Conclusion

In conclusion, pipe leaks in activated carbon systems can have severe implications for industries relying on these systems for purification and contaminant removal. Prompt repair of pipe leaks is crucial to ensure the efficiency and longevity of the system.

By understanding the importance of activated carbon systems and the potential risks associated with pipe leaks, you can take proactive measures to detect and address these issues early on. Regular inspections, preventive maintenance, and timely repairs are essential to avoid costly downtime, environmental damage, and compromised purification capabilities.

Remember, the key to maintaining an effective activated carbon system lies in preventive measures. By implementing proper maintenance protocols and promptly addressing pipe leaks, you can ensure that your system operates at its full potential, providing clean air and water for your industrial processes.

If you require assistance with pipe leak repair or preventive maintenance for your activated carbon system, don’t hesitate to seek professional help. Their expertise and experience can make a significant difference in the long-term performance and reliability of your system.

Together, let’s prioritize the repair and maintenance of pipe leaks in activated carbon systems to safeguard the efficiency, productivity, and environmental sustainability of our industries.