Introduction

Did you know that your plumbing system could be at risk of contamination? Well, that’s where backflow preventer inspection comes into play. In this article, plumbingrepairtips.com will delve into the world of backflow preventers and uncover their crucial role in maintaining the integrity of your plumbing system. So, let’s get started!

When it comes to ensuring the safety and purity of our water supply, backflow preventer inspection is an absolute must. These unsung heroes of plumbing systems work diligently to prevent the backward flow of water, which could potentially lead to contamination. Imagine the havoc that could be unleashed if pollutants, chemicals, or even sewage found their way back into our clean water supply. That’s where a well-maintained and regularly inspected backflow preventer steps in to save the day.

But what exactly is a backflow preventer? Well, it’s a device that allows water to flow in one direction while preventing it from reversing course. This vital component is typically installed at key points in your plumbing system where the risk of backflow is highest, such as where potable and non-potable water lines intersect. Its primary function is to safeguard against the contamination caused by cross-connections, ensuring that clean water remains clean.

Now that we have a basic understanding of backflow preventers, let’s dive deeper into the reasons why their inspection is of paramount importance. Stay tuned to discover the potential risks and consequences of neglecting backflow preventer inspection, as well as the legal requirements and benefits associated with regular maintenance.

Remember, protecting our water supply is a collective responsibility, and by being proactive in maintaining our plumbing systems, we can ensure a safer and healthier environment for ourselves and future generations. So, let’s explore the world of backflow preventer inspection together and learn how we can keep our water clean and our plumbing systems running smoothly.

Stay tuned for Understanding Backflow Preventers, where we’ll explore the different types and components of these crucial devices.

Understanding Backflow Preventers

Definition and Function of Backflow Preventers

To truly grasp the importance of backflow preventer inspection, we must first understand what these devices are and how they function. Backflow preventers are mechanical valves designed to prevent the reverse flow of water within a plumbing system. They act as a barrier, ensuring that water only flows in one direction, preventing any contamination from entering the clean water supply.

Various Types of Backflow Preventers and Their Applications

Backflow preventers come in different types, each designed to suit specific applications and levels of protection. The most common types include:

- Atmospheric Vacuum Breakers: These simple devices utilize atmospheric pressure to prevent backflow. They are commonly found in residential irrigation systems.

- Pressure Vacuum Breakers (PVB): PVBs are commonly used in commercial and residential settings. They employ a spring-loaded check valve and an air inlet valve to prevent backflow.

- Double Check Valve Assemblies (DCVA): DCVAs provide an additional layer of protection by utilizing two check valves. They are commonly used in industrial and commercial settings.

- Reduced Pressure Zone Assemblies (RPZ): RPZ backflow preventers are the most reliable and robust type, often required by building codes. They utilize two check valves and a relief valve, offering the highest level of protection against backflow.

Common Components of a Backflow Preventer System

Regardless of the type, backflow preventer systems consist of several key components:

- Inlet and Outlet Pipes: These pipes facilitate the flow of water into and out of the backflow preventer.

- Check Valves: Check valves are crucial components that allow water to flow in one direction while preventing backflow.

- Air Gaps: An air gap is a physical space between the water outlet and a potential source of contamination, providing an extra layer of protection.

- Relief Valve: Some backflow preventers, such as RPZs, incorporate a relief valve to release excess pressure and prevent damage to the system.

By understanding the different types of backflow preventers and their components, we can better appreciate the significance of regular inspection and maintenance. In the next section, we will explore the potential risks and consequences associated with neglecting backflow preventer inspection.

Stay tuned for Importance of Regular Inspection, where we’ll delve into the potential risks, legal requirements, and benefits of regular backflow preventer inspection.

Steps for Conducting a Backflow Preventer Inspection

Inspecting your backflow preventer is a crucial task to ensure its effectiveness in protecting your water supply from contamination. By following these steps, you can conduct a thorough inspection and maintain the integrity of your plumbing system.

Pre-inspection Preparation and Gathering Necessary Tools

Before starting the inspection, it’s essential to gather the necessary tools and equipment. You may need a flashlight, a pressure gauge, a flow meter, and a backflow preventer test kit. Ensure that you have access to the manufacturer’s instructions or technical specifications for your specific backflow preventer model.

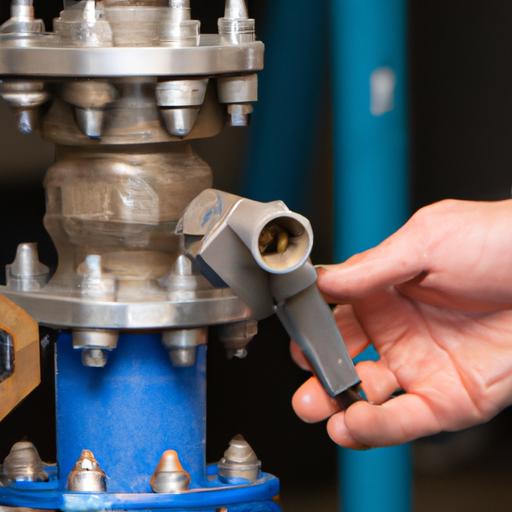

Visual Inspection of Backflow Preventer Components

Begin the inspection by visually examining the backflow preventer components. Look for any signs of wear, corrosion, leaks, or damage. Check the valves, relief ports, test cocks, and any associated pipes for any visible issues. Pay close attention to gaskets, O-rings, and seals, as they can deteriorate over time.

Testing the Functionality of Backflow Preventer Valves

Once the visual inspection is complete, it’s time to test the functionality of the backflow preventer valves. Start by slowly closing the downstream shut-off valve to create a pressure differential. Observe the valves to ensure they are closing properly and preventing backflow. Additionally, check for any abnormal noises or vibrations during the valve operation.

Conducting Pressure and Flow Tests to Ensure Proper Operation

To further evaluate the backflow preventer’s performance, conduct pressure and flow tests. Use a pressure gauge to measure the inlet and outlet pressures. Compare the readings with the manufacturer’s specifications to ensure they fall within the acceptable range. Additionally, measure and record the flow rate to verify that it meets the required standards.

Documentation of Inspection Findings and Recommendations

Throughout the inspection process, document your findings and observations. Take notes, capture photographs if necessary, and record any abnormalities or issues encountered. Based on your inspection, provide recommendations for any necessary repairs, replacements, or maintenance actions. This documentation will serve as a valuable reference for future inspections and ensure the ongoing reliability of your backflow preventer.

By following these systematic steps, you can effectively inspect your backflow preventer and take the necessary actions to maintain its optimal functionality. Remember, regular inspections are crucial to safeguarding your water supply and promoting a healthy plumbing system.

Stay tuned for Common Issues Found During Inspection, where we’ll explore the common problems that may arise during a backflow preventer inspection and how to address them.

Common Issues Found During Inspection

When conducting a backflow preventer inspection, it is essential to be aware of the common issues that can arise. By identifying and addressing these problems promptly, you can ensure the optimal functioning of your backflow preventer system. Let’s explore some of the most frequent issues encountered during inspections and discover how to effectively troubleshoot them.

Identifying and Troubleshooting Common Problems with Backflow Preventers

During your inspection, you may come across several common issues that can hinder the proper operation of your backflow preventer. One such problem is leaks. Leaks can occur at various points within the system, including valves, fittings, or even the backflow preventer itself. By carefully inspecting the system and pinpointing the source of the leak, you can take the necessary steps to repair or replace the faulty component.

Another issue that may arise is blockages. Over time, debris, sediment, or mineral buildup can accumulate within the backflow preventer, obstructing the free flow of water. This can compromise the effectiveness of the device and increase the risk of backflow. Regular inspection allows you to detect and clear any blockages, ensuring the smooth operation of the system.

Improper valve operation is yet another common issue that can be identified during inspection. Valves may fail to open or close fully, leading to inadequate backflow prevention. This can occur due to mechanical faults, corrosion, or wear and tear. By testing the functionality of the valves during inspection, you can determine if any adjustments or replacements are required.

Addressing Issues such as Leaks, Blockages, and Improper Valve Operation

When it comes to addressing issues with backflow preventers, leaks should be promptly repaired to prevent water wastage and potential contamination. Depending on the severity of the leak, you may need to replace seals, gaskets, or even the entire backflow preventer unit. It is crucial to consult with a professional plumber if you are uncertain about the extent of the damage.

If blockages are detected, they can usually be cleared by flushing the system or using specialized cleaning solutions. However, in cases of severe blockages, it may be necessary to disassemble certain components for a thorough cleaning. Regular maintenance and periodic cleaning can help prevent blockages from occurring in the first place.

When addressing improper valve operation, it is important to assess the cause of the issue. In some cases, a simple adjustment or lubrication may suffice. However, if the valves are severely damaged or corroded, they may need to be replaced. A professional plumber can provide expert guidance and ensure proper valve functionality.

By promptly addressing these common issues, you can maintain the efficiency and reliability of your backflow preventer system. Regular inspection and maintenance play a vital role in mitigating potential risks and ensuring the uninterrupted protection of your water supply.

Stay tuned for Conclusion, where we’ll recap the importance of backflow preventer inspection and highlight the role of plumbingrepairtips.com in providing valuable information.

Conclusion

In conclusion, the inspection of backflow preventers is an indispensable aspect of maintaining a safe and contaminant-free plumbing system. By understanding the importance of regular inspections, we can ensure the integrity of our water supply and prevent potentially hazardous situations.

Throughout this article, we explored the vital role that backflow preventers play in preventing contamination. We discussed their definition, function, and various types, including atmospheric vacuum breakers, pressure vacuum breakers, and reduced pressure zone devices. Understanding these different types and their applications is essential in selecting the right backflow preventer for your specific plumbing system.

We also delved into the common components of a backflow preventer system, such as check valves, air gaps, and test ports. These components work together to ensure the proper functioning of the backflow preventer and maintain the integrity of the water supply.

Regular inspection of backflow preventers is not only essential for preventing contamination but also mandated by legal requirements and regulations in many jurisdictions. By adhering to these regulations and conducting thorough inspections, we can ensure that our plumbing systems meet the highest standards of safety and compliance.

Remember, neglecting backflow preventer inspections can have severe consequences, including potential health risks and legal liabilities. By taking proactive measures and scheduling routine inspections, you can safeguard your plumbing system and protect your family and the environment.

If you’re unsure about conducting a backflow preventer inspection yourself, it’s always best to consult a qualified professional. They have the expertise and knowledge to identify any issues and provide appropriate solutions.

In conclusion, prioritizing backflow preventer inspections is crucial for maintaining a safe and reliable plumbing system. By doing so, we can ensure that our water supply remains clean and free from contamination. Remember, at plumbingrepairtips.com, we strive to provide you with the knowledge and resources you need to tackle any plumbing issue. Stay informed, stay proactive, and keep your plumbing system in tip-top shape.

Thank you for joining us on this journey to understand the importance of backflow preventer inspections. If you have any questions or would like to share your thoughts, feel free to reach out to us. Together, let’s make sure our plumbing systems are equipped with reliable backflow preventers to protect our precious water supply.